Turbocharging

vs. Supercharging

By: Toma Kicovic,

B.Sc.

Lately there has been a lot of BS floating

around on this subject, and a lot of people seem to be confused on the basic

principles of the two systems.

I will be comparing the centrifugal type

of superchargers to the turbo system. Centrifugal blowers are very efficient in

their functioning, and I will discuss what this efficiency means. Centrifugal

superchargers include compressors marketed under such names as Vortech, Paxton,

Powerdyne, ATI, etc...

What Turbos and Supercharger Have in Common

What is in

common, is that both systems use a centrifugal compressor section to compress

the incoming air to higher than atmospheric pressures. Normal or standard

atmospheric pressure is about 14.7 psi (pounds per square inch). The job of the

compressor is to increase this pressure so that more oxygen content (air) is

available to fill the cylinders. This is really not a very technical

explanation, but is meant to be quite general.

What is in

common, is that both systems use a centrifugal compressor section to compress

the incoming air to higher than atmospheric pressures. Normal or standard

atmospheric pressure is about 14.7 psi (pounds per square inch). The job of the

compressor is to increase this pressure so that more oxygen content (air) is

available to fill the cylinders. This is really not a very technical

explanation, but is meant to be quite general.

Both systems offer very good efficiency.

When properly matched to the air flow characteristics of the motor, efficiencies

in the 70 and 80% range can be had. When you compress a gas, its temperature

will increase, so effciency is basically how much heat is introduced compared to

the level of compression (the less heat, the higher the efficiency). I won't get

more technical than that, but 75% is generally considered very efficient (as a

comparison, old style roots blowers were only about 50% efficient).

Both Turbos and Superchargers require high

rpm of their impellers (compressors) to achieve a given boost level. This rpm

ranges from 30,000-65,000 in superchargers and can be even higher with turbos

(over 100,000!).

What is Different

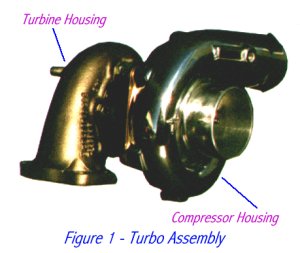

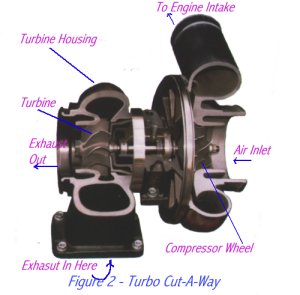

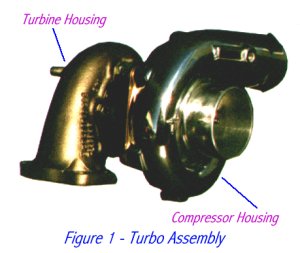

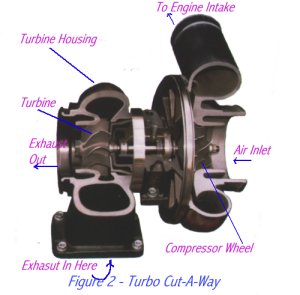

The major difference is in the drive

system of the 2 systems. A turbocharger's compressor section is connected

directly by a shaft to the turbine housing. The turbine is the portion of the

turbo that takes exhaust energy (heat and pressure) and converts it to motion.

Since the turbine and the compressor are connected by a shaft, the compressor

spins at the same rate as the turbine.

The major difference is in the drive

system of the 2 systems. A turbocharger's compressor section is connected

directly by a shaft to the turbine housing. The turbine is the portion of the

turbo that takes exhaust energy (heat and pressure) and converts it to motion.

Since the turbine and the compressor are connected by a shaft, the compressor

spins at the same rate as the turbine.

On a supercharger, the compressor section

is connected to a step up mechanism (gears, belts, pulleys or whatever) and then

to the engine drive belt. The step up mechanism is required to convert the 6000

(or so) engine rpm, to the 40,000+ rpm necessary to build boost.

Centrifugal compressors build boost as rpm

increases in close to an exponential fashion. Turbo's come up to speed very

quickly (almost instantly if properly sized), and once a desired boost level is

reached, excess exhaust gas is bypassed around the turbine by a 'waste gate'.

What this does is limit the speed of the compressor (and turbine) and therefore

boost. The point where the waste gate opens can be set so as to produce a

desired rpm and boost level. With a turbo then, as soon as there is sufficient

exhaust flow, the turbine will come to speed, and you can have full boost within

a fraction of a second. A properly sized turbo can achieve its maximum boost

setting at almost any rpm you desire, on a 6000rpm motor, this can be as low as

about 2500rpm.

A supercharger on the other hand relies

on engine rpm to come up to speed, so maximum boost wont 'come on' until higher

rpm. If you buy a supercharger marketed as an 8psi kit, that generally is the

maximum boost on a stock engine. But due to it exponential nature, boost will

quickly drop with rpm. If your kit makes 8 psi at 6000 rpm, it will generally

make less than 2.5 psi at 3000rpm.

Performance Differences

So far we have seen that due to the nature of the

centrifugal compressor design, a turbo will reach its target boost level much

quicker than a belt driven supercharger. Are there any other differences?

It takes power to pump (compress) a large

volume of air (700+cfm). The supercharger's power is derived directly from the

crank shaft, where as a turbo's power comes from energy contained in the exhaust

gasses. On a typical 8 psi supercharger, the power used can be in the

neighborhood of 40-60hp! On a 1500hp engine, the power used by the supercharger

can be as much as 300hp! This would leave only 1200hp to accelerate the

car.

A turbo is not entirely 'free' horsepower

as some additional back pressure is created by the turbine, but a turbo derives

a very large portion of its energy from heat. This is shown by the fact that

exhaust gas temperature can drop by as much as 300 degrees Fahrenheit as it

leaves the turbine housing. In essence the power 'robbed' by the extra back

pressure is very small (also due to other more 'complicated' factors like

critical exhaust flow, but we wont get into that here).

So what does this all mean? Basically an 8

psi turbo kit will produce more peak power due to the fact that a supercharger

is using a fairly large amount of power just to get it spinning. What is more

important for a street car is 'power under the curve' meaning the average

horsepower produced. This is where the turbo really shines since you can have

full boost at as little as 2500 rpm! This will make the turbo car feel like it

has 50% more cubic inches (or more). The difference in torque at low rpm's can

be as much as 100 lb ft in favor of the turbo due to the additional available

boost....now that's performance!

Who Makes a Good Turbo Kit and Is It Complicated or Expensive?

Several manufacturers offer good turbo systems. The

one I chose for my Mustang was manufactured by INCON Systems. Two other manufacturers

who's kits work well are the ones from Cartech and TurboTechnology.

The INCON kit is hands

down the best "street" kit I have ever seen (capable of over 800hp!),

however, I am not sure if INCON is even in business any more. There are occasionaly

used INCON kits on ebay, and often older DDMI kits are passed off as Incon kits,

even though there are some HUGE differences....buyer beware!

The "Home Made" route

is also a great way to go for the DIY'ers. Many people have gone this route,

and if you are handy, can weld, and are willing to do a lot of swearing, you

may opt for this method. Common turbos used are T3's from early Tbirds, Mustangs

etc, some diesel turbos etc... A great place to learn and ask question is on

the Yahoo Groups sites.... JYTurbo (junkyard turbo) is http://groups.yahoo.com/group/jyturbo/

and another good one is the "BlowThru" list (people who run carburetors

with their turbos) http://groups.yahoo.com/group/BLOWTHRU/

. There are a fe other links on my personal turbo page at http://www.members.tripod.com/tomak3/page5.html

.

After Thoughts

I originally wrote this article

a few years ago, and have seen it referenced several times since....kinda flattering.

I have not chnaged it very much as the basic concepts still apply. I love both

turbos and superchargesr, and even big blocks on nitrous ;). My honest opinion

is that a turbo set-up will outperform a supercharger set-up, however, for the

begginer, the supercharger is a simpler and more user friendly system.

I have done quite a bit of research

on the subject and have read several books on it as well (Maximum Boost - Corky

Bell, Turbocharging - Hugh MacInnes, Street Supercharging - Pat Ganahl, Performance

With Economy - David Vizard, 21st Century Performance - Julian Edgar)). I was

always fascinated by how an Indy car with less than 100 cubic inch turbo engine

could make over 1000hp, or how some of the 4 litre Turbo Buicks could make 1000+hp.

What impressed me the most was how docile some of the high horsepower turbo

cars were (mainly due to the smaller cams). The fact that turbos are banned

and have been banned in many classes of racing also illustrates their effectiveness....other

competitors are scared of them! When Hurley Bleakeny set the door slammer mph

speed record several years ago in his T bird, it was with a turbo motor.

I also once owned a

2.3 litre turbo Merkur Xr4Ti, and was VERY impressed how with only bigger

exhaust and hand ported intake and more boost, the car could easily beat stock

V8 cars (Mustangs, Corvettes etc...). It also had a top speed of 240 km/h, which

was limited by gearing NOT by power. This car was not even

intercooled.

After my experience

with the Paxton supercharger on my first Mustang, I really wanted to build my

own turbo kit (due to lack of bottom end torque), but was limited in my abilities

and finances at the time and the result was the 460 big block conversion in

the black car. Also after the Powerdyne car, I again had my 'flame' re-sparked,

and decided to go for it. I actually had 1 turbo from a Tbrid and a line on

2 intercoolers from Toyota Supras. That was when I heard about INCON and their

kit, and decided to forgo months of fabrication and experimentation and buy

a complete, ready to bolt on kit.

Questions? Email me!

BACK

TO HOME

What is in

common, is that both systems use a centrifugal compressor section to compress

the incoming air to higher than atmospheric pressures. Normal or standard

atmospheric pressure is about 14.7 psi (pounds per square inch). The job of the

compressor is to increase this pressure so that more oxygen content (air) is

available to fill the cylinders. This is really not a very technical

explanation, but is meant to be quite general.

What is in

common, is that both systems use a centrifugal compressor section to compress

the incoming air to higher than atmospheric pressures. Normal or standard

atmospheric pressure is about 14.7 psi (pounds per square inch). The job of the

compressor is to increase this pressure so that more oxygen content (air) is

available to fill the cylinders. This is really not a very technical

explanation, but is meant to be quite general.

The major difference is in the drive

system of the 2 systems. A turbocharger's compressor section is connected

directly by a shaft to the turbine housing. The turbine is the portion of the

turbo that takes exhaust energy (heat and pressure) and converts it to motion.

Since the turbine and the compressor are connected by a shaft, the compressor

spins at the same rate as the turbine.

The major difference is in the drive

system of the 2 systems. A turbocharger's compressor section is connected

directly by a shaft to the turbine housing. The turbine is the portion of the

turbo that takes exhaust energy (heat and pressure) and converts it to motion.

Since the turbine and the compressor are connected by a shaft, the compressor

spins at the same rate as the turbine.